A question we often get asked is if employers need to have annual racking inspections conducted by a third party expert?

The short answer?

Yes! (If you want to comply with the regulations).

The long answer?

Strap yourselves in! This is where we get technical…

Below we have highlighted some key extracts from UK Guidelines and Legislation. It is by no means exhaustive, and as with all legal guidance, we always recommend employers seek a legal professional for any concerns or advice.

The legal requirement for work equipment inspection (including storage equipment) is established primarily under The Provision and Use of Work Equipment (PUWER) 1998.

Regulation 6 – Inspection

(1) Every employer shall ensure that, where the safety of work equipment depends on the installation conditions, it is inspected –

(a) after installation and before being put into service for the first time; or

(b) after assembly at a new site or in a new location, to ensure that it has been installed correctly and is safe to operate.

(2) Every employer shall ensure that work equipment exposed to conditions causing deterioration which is liable to result in dangerous situations is inspected –

(a) at suitable intervals; and

(b) each time that exceptional circumstances which are liable to jeopardise the safety of the work equipment have occurred, to ensure that health and safety conditions are maintained and that any deterioration can be detected and remedied in good time.

But wait, there’s more…

“I asked about annual inspections” we hear you shout!

The Health and Safety Executive (HSE 76) gives the following guidance:

‘Expert’ inspections

646 A technically competent person should carry out inspections at intervals of not more than 12 months. A written report should be submitted to the PRRS (person responsible for racking safety) with observations and proposals for any action necessary.

647 A technically competent person might be a trained specialist within an organisation, a specialist from the rack supplier, or an independent qualified rack inspector.

(Source: HSG (76) Warehousing and Storage, A Guide to Health and Safety, Second Edition 2007)

Note: a trained specialist within an organisation would be someone with an appropriate qualification. Typically, a one or two day rack safety awareness course offered by our friends at Rack Group may help new and existing staff who work in and around pallet racking on a daily basis understand the implications of damaged pallet racking, but would not give the level of competence to define an individual as a ‘trained specialist’. However they do offer higher level racking inspection training courses.

In summary:

If you skimmed over that last section (no judgement!) the key things to know are that racking should be inspected:

- When you install it

- If you move it

- At regular intervals

- Every time something jeopardises its safety (e.g. a forklift truck accidentally reversing into it)

- At least once a year by a technically competent person

Regular racking inspections not only ensure you stay legally compliant, but also ensure any safety risks are picked up instantly. Identifying (and rectifying) damage as it happens means you reduce the risk of racking collapsing, damage to your property, as well as serious injury to your staff.

There’s also a financial risk. The HSE could fine an employer if it’s evident they have not taken the necessary steps to adhere to these guidelines.

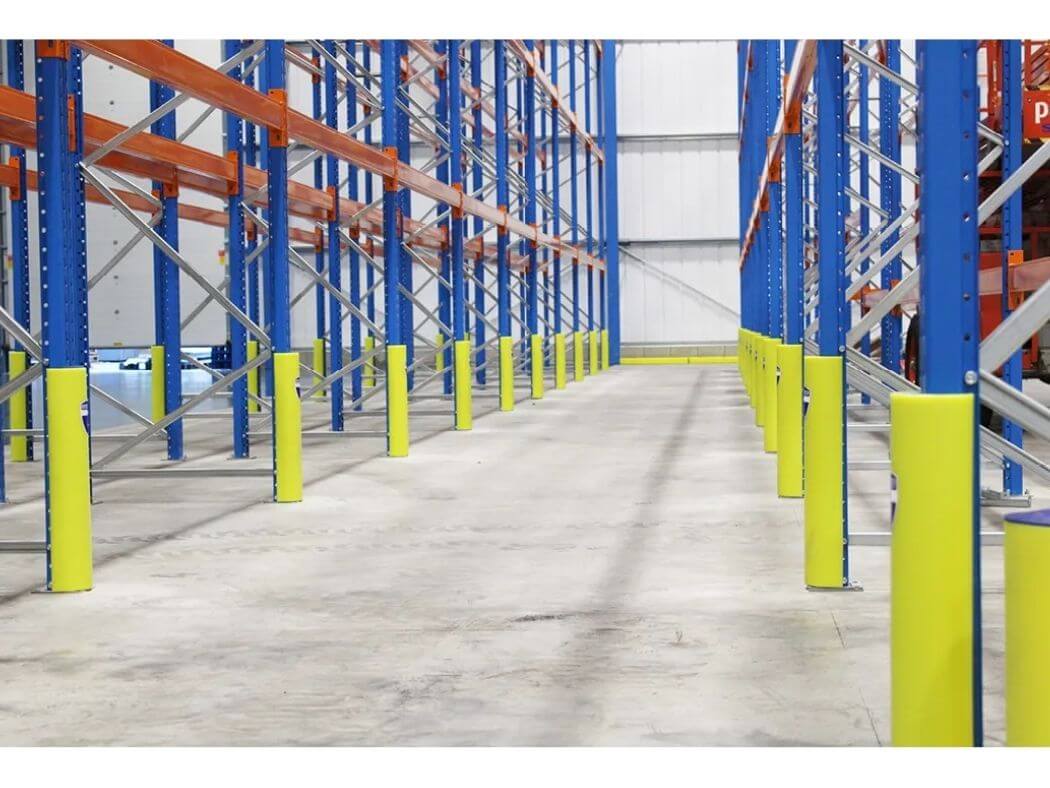

To help prevent damage occurring to your racking take a look at our popular racking upright protectors.